On Thursday one of the fluorescent fixtures in my sutdio began to flicker. On Friday it was mostly dark except for when it flashed intermittently, like a camera flash. Very annoying.

What usually happens in this case is that we replace the fixture. We've always bought into the idea that changing the ballast in a fluorescent fixture was just too hard. Well, this fixture matches the other one in the room AND Steve was busy in Chris's bathroom. I knew I couldn't change the whole fixture on my own because it is too heavy and unwieldy. But maybe I could change the ballast… I turrned to Google and found the following video by Oscar Moreno. Oscar makes it look really easy…

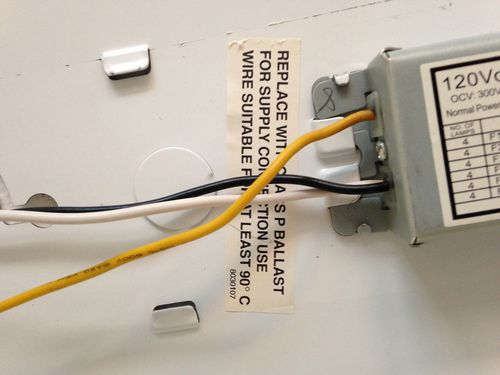

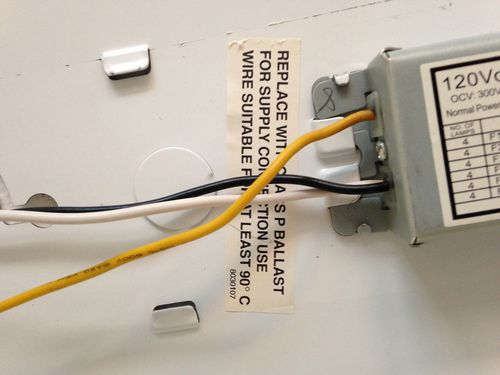

I did turn off the power to light at the breaker box. Didn't want to electrocute myself. I took off the plastic cover, then the bulbs, took off the cover to the ballast and wires. At one end there are 3 wires – black and white are power, the yellow is whatever it is. You can also see the slot at this end that the end of the ballast fits under.

The other end of the ballast had more wires – red, blue, brown and gray. And a nut that holds the ballast in place. I cut the wires close to the end of the ballast, undid the nut, and took it to Lowe's to find a replacement.

The replacement ballasts were a different brand and they didn't have as many wires coming out. Very confusing. The very nice man (who tried not to be exasperated) explained to me that the number of wires didn't matter. He even took a fixture out of the box to show me what to attach where. I decided to trust him.

Once home, I put the new ballast in place and puzzled over how to make all the wires come together. My fixture had two wires in every place that there could have (should have?) been one wire. So I decided to join the one wire from the ballast to the two wires that matched up with the diagram on the ballast. If you look at the photo below I attached a blue from the ballast to the two blues on the fixture; then a blue from the ballast to the two reds on the fixture; etc. The yellows went together.

If you have not done this before you may not know that the wires are covered in plastic insulation. You have to carefully cut the plastic, but not the wire, and then pull the plastic off – exposing about 1/2" of wire. This is called stripping the wire. That was the hardest part. I did a couple but then Steve came home for lunch and stripped the rest for me.

I used the orange wire nuts to hold the wires together. They are simple yet effective. You stick the wires to be joined into the nut and twist. You can see the tools I used below/ That flat thing is a wire stripper that my dad made many, many years ago.

Once the wiring was done I put it back together and reinserted the bulbs. I wasn't sure they would work, but they did! I switched on the breaker and there was light.

I saved some money by doing this, and time because changing the fixture takes longer than this did. I also kept the old fixture out of the landfill. I am inordianantly proud of myself :-). I also want to share the news that this is not a hard thing to do.