If you have read my blog long, you know that Steve and I usually work on some sort of big ‘house’ project during the summer. Since we just had our house remodeled last year, we don’t have a project to do at our house. We helped Chris with his bathroom remodel in the spring and early summer. Now what?

We decided to work on the McCarley Woods. Howard and Marian McCarley donated a wonderful property to Austin College a few years ago. It is primarily used by faculty and students in the biology department.

The cabin on the property is solid but needs a bit of spiffing up. Steve and I decided that this would be a great project but first we needed a place to put the tools that are occupying one of the bedrooms. Se we decided to build a shed!

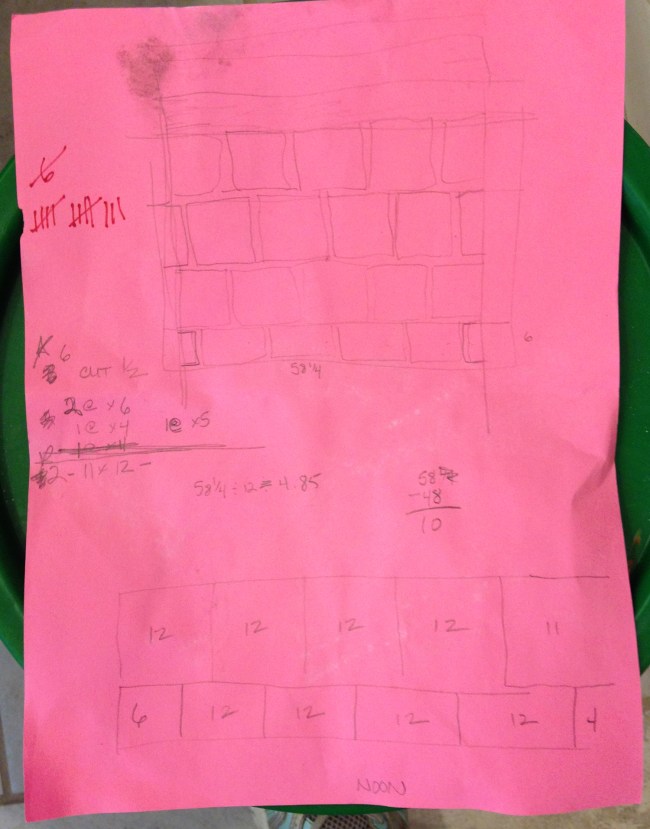

Steve designed an 8′ x 8′, pier and beam structure. Last weekend he put in the foundation and built the framework for the front and back wall. Tuesday morning (after Pilates) I showed up to do my part which is to be both foreman and gopher.

I helped him raise the end walls and secure them in place. Then the framing for the side walls went up. After that, we added the 2′ tall extension that he had prepared to the top of the front wall. The roof will slope from front to back.

Christopher joined us after lunch and I, for one, was very happy. The siding is Hardie paneling and it is heavy! Drilling holes and driving screws through it was hard on their hands… I have a feeling I could not have done it at all.

Once the back and two sides were paneled, Steve and I hoisted and slid 4′ x 8′ sheets of chip board up to Chris, who nailed them to the rafters. Next we sent up metal roofing sheets. All of that sounds a lot easier than it was :-).

It was a long day and we called it quits at 6:00. Wednesday it rained. Luckily I had found time to put a coat of water seal on the plywood floor while the guys were doing other things so it didn’t peel apart.

This morning Steve went out early (because I went to Pilates again) and started getting Hardie panels cut and installed on the front wall.

I helped him get the remaining, small wall panels up. Next we worked on enclosing the roof rafters to keep the critters out. And we wanted to trim out the corners of the shed before we broke for lunch. At some point it started to drizzle, and then rain.

We were wet and muddy when we called it quits at 12:30. Steve is going to build the doors later and maybe we can hang them Saturday. We’ll paint the shed in a couple of weeks, when I am back after teaching in Indiana next week.

It is solid and functional. Once painted it might even be cute!

The windows weren’t lovely, but we lived with it until our job could be worked into the Caesarstone crew’s calendar.

The windows weren’t lovely, but we lived with it until our job could be worked into the Caesarstone crew’s calendar.